Drive out the old bushings and drive in the new. This is best done in a vise with a bushing driver. The bushings must be removed by driving them out of the spindle. If you buy a kit at a swap meet or online, be sure that you are getting a complete kit. Some installations require other special parts, but this list should be the minimum in the kit. There should be two king pins, four bushings, two bearings, shim packet, two lock pins with lock washers & nuts. Open the new king pin set and check the components. Industrial chroming is a very hard surface that can be used to save an otherwise difficult to find part. Another option would be to have the spindle industrial chromed and turned back to standard. If your spindles have this kind of damage, you can try to find suitable replacements. This in turn can cause irregular wear on tires or steering "wander". If a bearing race has spun, it can damage the spindle causing loose bearing fit and also causing misalignment. The damage will be on the bottom edge of the spindle surface which is holding the weight of the vehicle. With the spindle cleaned, inspect the bearing surfaces for signs of damage. Clean the axle and spindle of dirt and grease. Note the location of the bearings & shims as they are disassembled. Remove and discard the bearing but retain any undamaged shims for possible use later. With this pin removed, drive the king pin down and out of the axle and spindle.

Once the dust cap is removed, unbolt and remove the tapered lock pin that is bolted horizontally into the axle housing. Remove the dust cap (soft plug) on top of the spindle by striking it with a chisel on the edge. Clean the backing plate and set aside for installation later. Check the brake shoes for wear and wheel cylinders for leakage. With the bolts removed, the backing plate will slide off of the axle, exposing the spindle, axle and king pin. Remove these, taking note that some applications will have two different size and/or different length bolts. There will be four main mounting bolts that hold the backing plate to the spindle. Also cover the end of the brake hose with a plastic bag and seal with a rubber band. When removing hydraulic brake hoses press a rubber plug into the opening on the wheel cylinder. This would include brake housings and cables on mechanical brake systems or brake hoses on hydraulic systems. This plate must be removed but anything connecting the backing plate to the chassis must be removed first. This will expose the brake backing plate. With the hub removed, slide the inner bearing dust shield and inner race off of the spindle. Check closely for pitting in the balls or races.

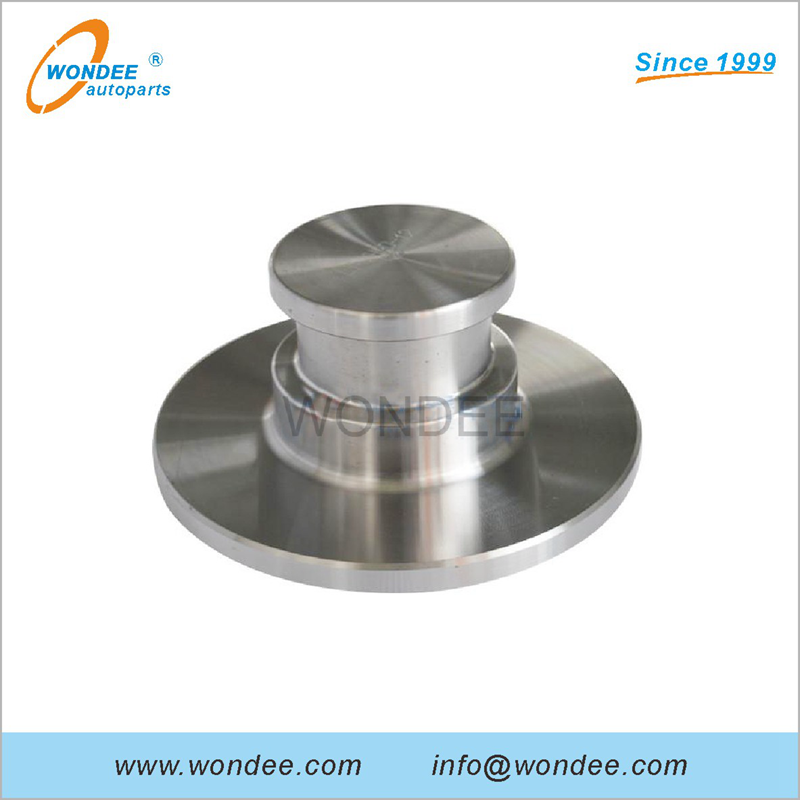

This is a good time to inspect the condition of the wheel bearings and repack them with fresh grease. Pull the hub & brake drum off while keeping the outer bearing from falling out of the hub. Remove the hub dust cover, cotter pin and spindle nut. Jack up the front of the vehicle and place it on good quality, four point jack stands. King pins on early Chevrolet cars and trucks require pressing bushings into the spindle and using a reamer to fit the pin to the bushings. The specific applications are:ġ931-1933 All passenger & 1/2 ton trucks (except 1933 std. So register just once and always benefit.This is a new reproduction set of king pins and bushings for 1928-1939 Chevrolet cars & trucks.

#Truck king pins registration#

As a thank you for your brand loyalty, there is a code on the item labels of many DT Spare Parts brand products that can be converted into crowns after registration in the Premium Shop and exchanged for high-quality rewards. If you, as the end user, regularly purchase DT Spare Parts brand products, you will not only benefit from the complete range of guaranteed quality and the comprehensive range of services. cars, agricultural vehicles, construction vehicles, marine or industrial applications, and many more. The DT Spare Parts brand from Germany provides a complete range with around 40,000 automotive parts and accessories suitable for millions of reference numbers - no matter whether for trucks, trailers, buses and transporters or other applications, e.g. Loyalty programme with exclusive premium shop.Extensive online services to support you.30 application-related product catalogues (digital and print).Your personal benefits with DT Spare Parts: If you have questions, please contact the Diesel Technic HelpDesk. For detailed information for the appropriate vehicles, please search using the item or reference number in the Partner Portal by Diesel Technic.

0 kommentar(er)

0 kommentar(er)